A Sticky Issue: Heat Shrink Tubing

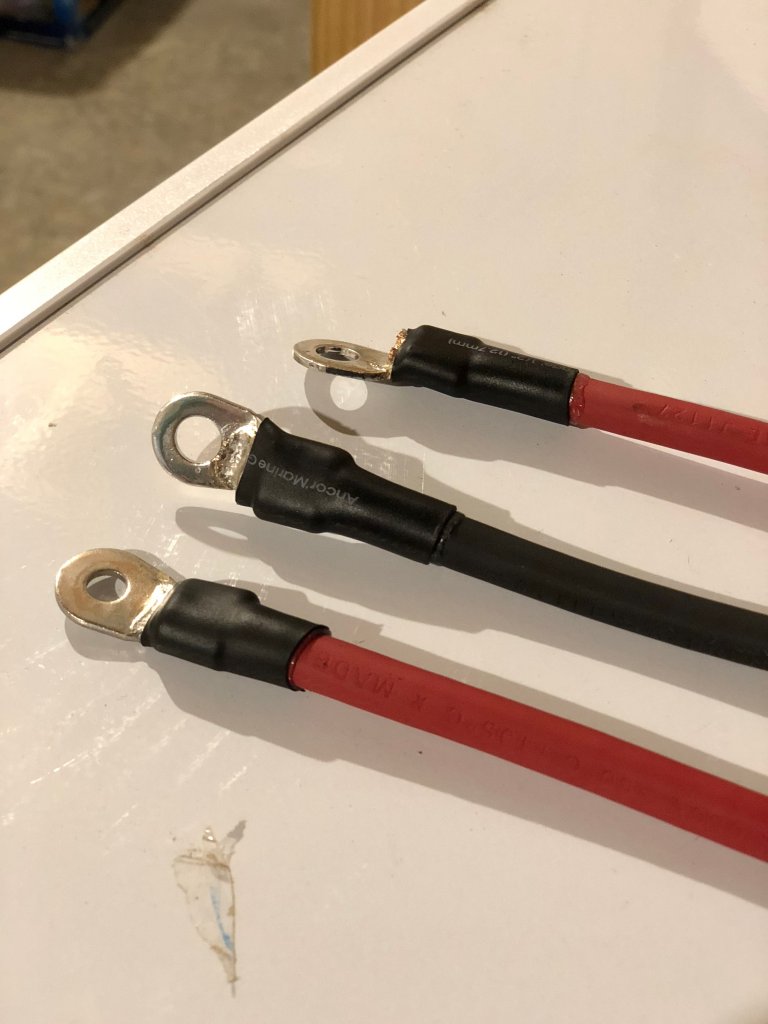

The best kept “not so secret” secret of people who are savvy with electrical, or the thousands of uses for shrink wrap tubing, is the illusive heat shrink tubing that is lined with adhesive.

“What’s that?” you say? Yes, there is a special version of this that has a gooey adhesive which melts and expands at the same temperature that the heat shrink shrinks. This ultra adhesive locks itself down onto whatever it touches and shifts some of the load for keeping the stuff inside onto the heat shrink itself. It also doubles as a waterproof barrier, and as such, this tubing is usually referred to as marine grade heat shrink.

The structural portion of the heat shrink tubing has the added benefit of helping to keep in-line wire splices together, if you are not 100 percent confident in the crimps of your butt splices, or if your soldering is more amateur than you would prefer. As we said before, there are thousands of uses for heat shrink tubing, from its intended purpose of protecting wiring, to being manipulated to be an end cap for a bolt or a sleeve for abrasion. If you can dream it, heat shrink can do it—and it is cheap. We found all of our marine heat shrink from McMaster Carr and Amazon and prefer the 3:1 shrink ratio for more usability across different applications.